Set and Assure Processes and Procedures in Consultation

‘ManualMaster provides clarity and insights. We used the application to centrally store our procedures and work instructions’, say Vera Smits and Vera Bunt, QA officers and ManualMaster managers at Ausnutria. ‘Thanks to the quality management system, employees can easily access the documents they need for their job. Version control and the authorizations of our documents are automated and the application offers documents for Read & Understand.’

Ausnutria produces infant formula, which explains why quality and food safety are so important for the company. The processes for producing good and safe products are assured thanks to the Quality Manual that the company produced with ManualMaster

Food Safety and Quality Requirements

Ausnutria applies the guidelines of the Codex Alimentarius, GB (China), and EU and Dutch legislation for infant formula and foodstuffs. The company also has the know-how to formulate recipes that are specifically tailored to local regulations and legislation in non-EU countries.

The production sites are certified according to (international) standards:

- FSSC22000 Food Manufacturing

- BRC Food

- GMP+ animal feed

Ausnutria is certified for the production of:

- Organic products

- Halal products

- Kosher products

All the raw materials and end products undergo extensive testing in accordance with food safety and quality requirements by external, accredited laboratories. The Netherlands Controlling Authority for Milk and Milk Products (Controle Orgaan voor Kwaliteitszaken (COKZ)) and various certification bodies regularly control the Ausnutria production sites.

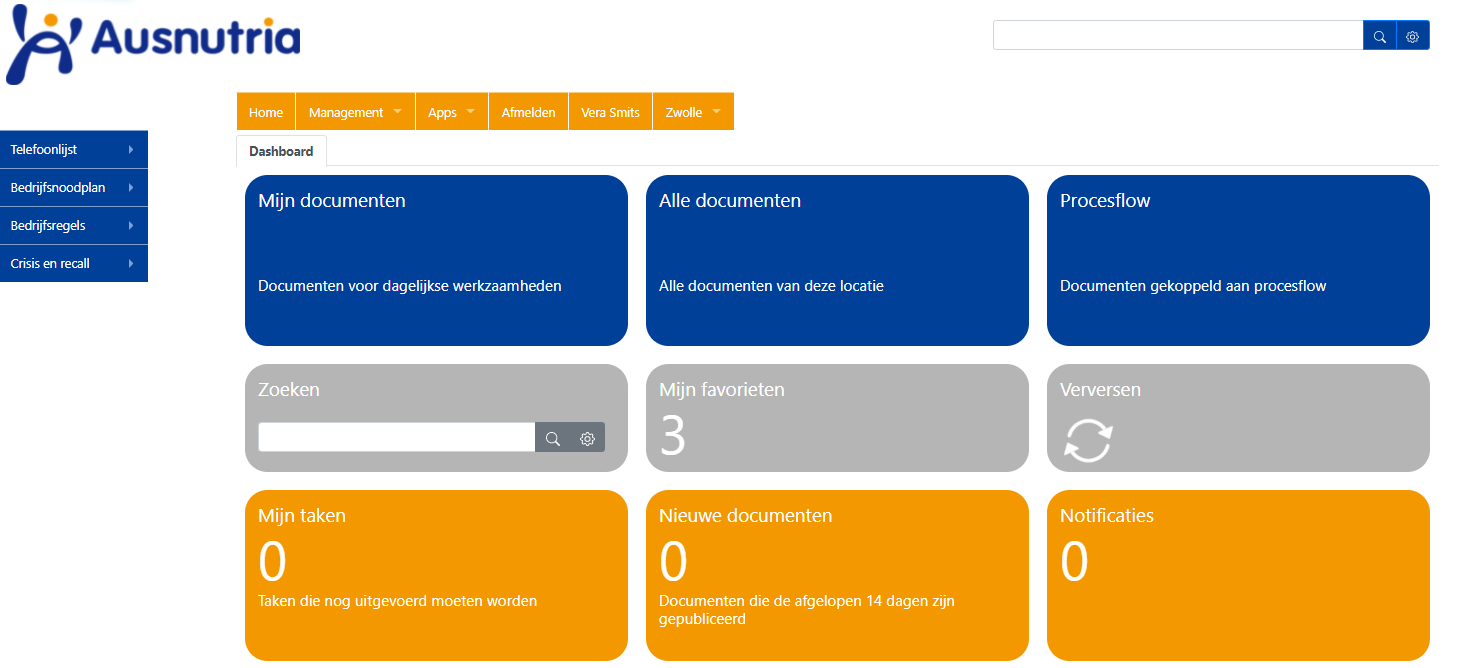

Ausnutria’s User-friendly, Simple Dashboard

Assuring and Establishing Processes and Procedures

ManualMaster contributes to the infant formula manufacturer’s quality management system with Document Management. They use this to set and assure processes and procedures in consultation.

Before Ausnutria switched to ManualMaster, the company largely relied on a Windows environment for its document management. Unfortunately this no longer proved sufficient.

‘We then looked for an effective and efficient document management system. We needed to create an authorization cycle and designate process owners, among others.’ The company started by building the system on one site. ‘We were able to easily roll it out to all of our other Dutch production sites. There are five in all.’

Risk Management in Procedures and Processes

Ausnutria is currently working on the implementation of the Risk Management module in procedures and processes. The Internal Control Department is using the module to understand how financial risks can be covered and secured. Thanks to Risk Management, the infant formula manufacturer is able to better describe and analyse risks and make sure that measures are taken to avoid incidents and risks.

At Document or User Level?

Approximately 900 Ausnutria employees have access to the software during the various production processes. Experience has shown that they find the system easy to learn. ‘They all receive an instruction sheet as a guideline. We have observed that employees find ManualMaster easy to learn’, the QA officers say.

‘Our one bit of advice for future ManualMaster users is to think very carefully about how you will organize the system. At document or at folder level? You should also think about which rights you will assign to users. And keep things as simple as possible.’

Quick Response Guaranteed

The two QA officers enjoy working with ManualMaster as an organization. ‘You can easily get in touch with them if you have a problem or a question. They are very accessible and respond immediately. This applies to both our account manager and the service desk. You never have to wait very long for an answer.’

by Ad Killian

together with Ronald de Bruijne / ManualMaster

About Ausnutria

| Core business | production of infant formula |

| Has worked with ManualMaster since | 2015 |

| Uses ManualMaster for | Document management (operational) – Risk management (under development) |